- Project

- Duke University Marine Laboratory

- Story Collection

- How is ALDB done?

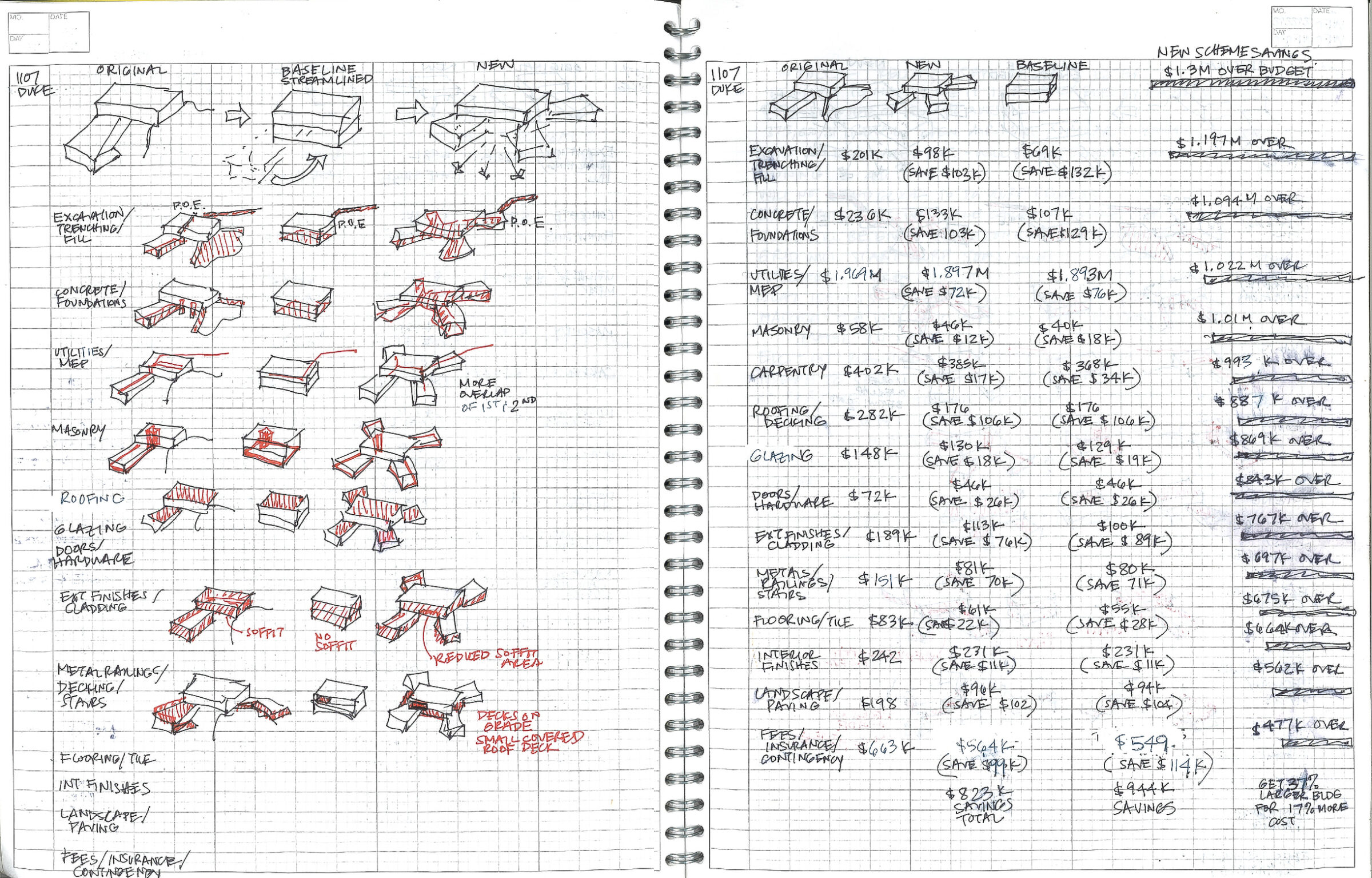

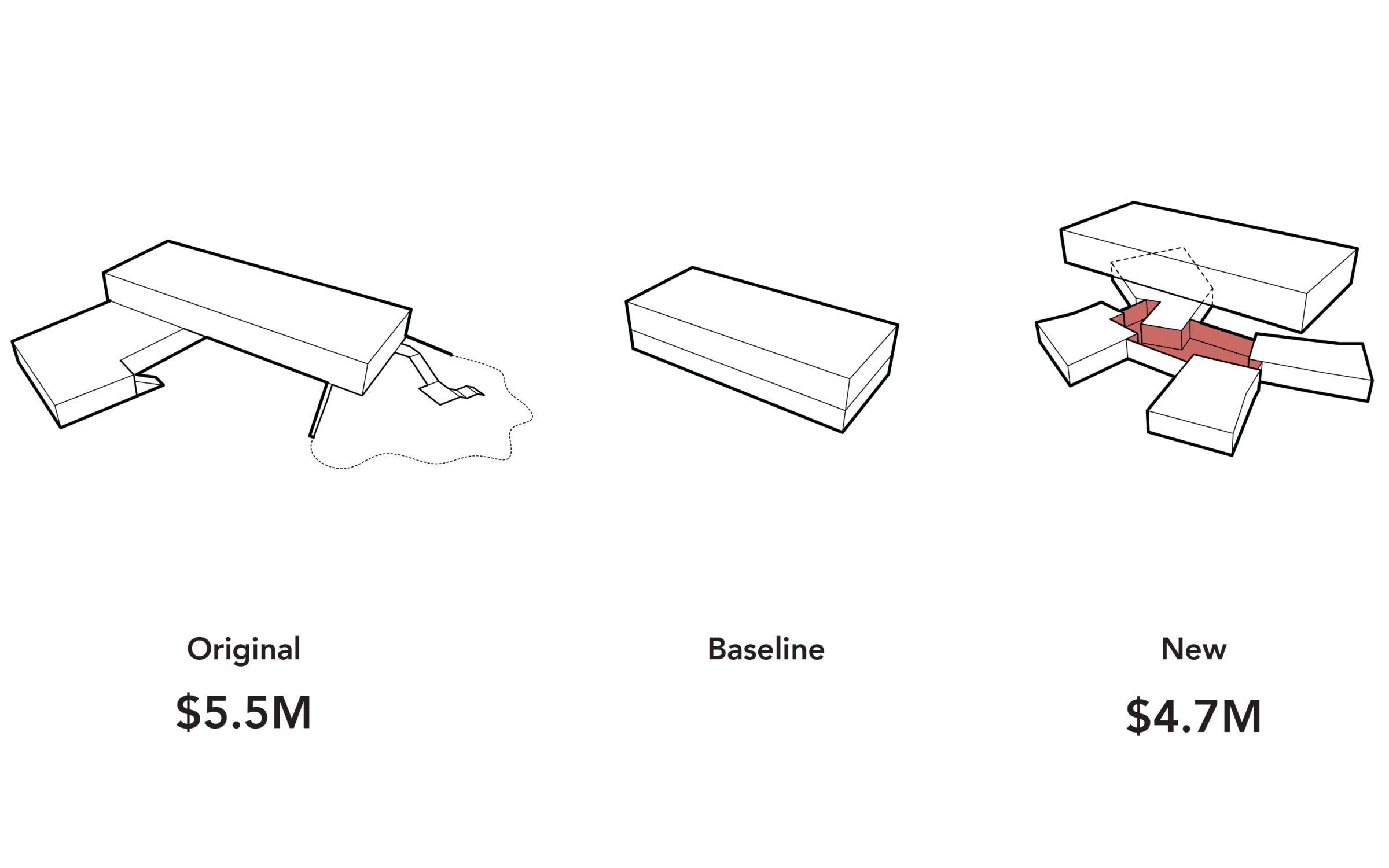

Duke University Marine Laboratory’s program was 37% larger than its budget. Rather than reducing the building’s size or limiting its program, we presented a comprehensive design that met all the client’s criteria. Preliminary pricing and scope sets for this first design tested the market and helped us understand the skills of local trades. The direct interaction with subcontractors, a key aspect of Architect-Led Design Build, determined a reduced trade-by-trade project cost, which was still $800,000 over the budget.

The next step was a one-month redesign period: the goal was to take money out of the building without compromising the program. To facilitate excavation and foundations, the building’s footprint was reduced, increasing the overlap between the first and second floors. This minimized MEP horizontal runs and decreased the amount of masonry, carpentry, and roofing. We also reduced the surface area of exterior cladding and soffits, identified lower-cost glazing systems, and positioned outdoor decks at grade to reduce stairs, railings, decking, and complicated roof details. Collaboration with local subcontractors to explore alternative systems for interior finishes guaranteed quality and cost savings. The compressed footprint simplified landscaping and paving, and with the lower construction cost, the associated fees, insurance, and contingency reduced accordingly.

This creative effort resulted in a building that met the client’s budget, delivered with a guaranteed maximum price (GMP).